Blog | Rainbow Inkjet | UV Printer | UV DTF Printer | DTF Printer | DTG Printer

How to Print Silicone Products with a UV Printer

What is the Silicone That We Are Talking About?

Silicone, also known as silicone resin, comes in various forms including silicone oil, flexible and elastic silicone gel, silicone rubber, and rigid silicone resin. Silicone is chemically stable and does not burn. The silicone products we refer to here are also called silicone rubber, which is one form of silicone resin. Silicone products with different manufacturing processes will have varying hardness and surface properties. One type of silicone product that is difficult to print on has a layer of silicone oil on the surface. As we know, oil is very smooth and most materials do not adhere well to it. Therefore, directly printing patterns on silicone products with a UV printer is usually not possible.

Phone cases are a common silicone product used for UV printing. For example, some official Apple phone cases are made of solid high-temperature vulcanized silicone rubber, which is soft, impact-resistant, and tear-resistant. These types of products are also applicable to the applications discussed in this article.

How to UV Print Silicone Products?

So how can we directly print on silicone using a UV flatbed printer? The silicone itself needs to be pre-treated before printing. There are generally three pre-treatment methods:

Apply a silicone coating before printing

Before printing, a silicone coating can be manually sprayed or wiped onto the surface, then printing can be done directly and the prints will not fade. This method generally works for relatively hard silicone products, commonly used on kitchen utensil handles.

Flame treat, then apply silicone coating

Because the silicone surface material is unique, flame treating it first causes surface changes so that when a silicone coating is applied after, the prints will not fade. This method works for softer, more flexible silicone products that require more treatment.

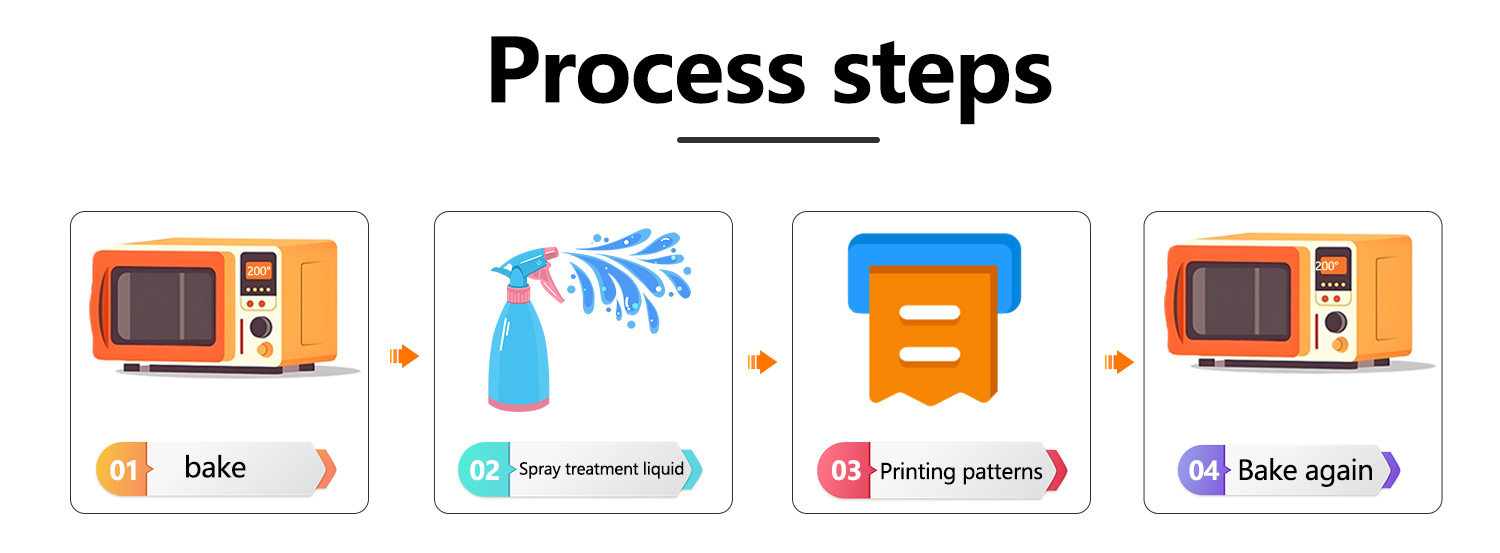

Bake, apply the coating, then bake again

First, bake the silicone in an oven at around 200°C for 20-30 minutes before printing. Baking helps remove the silicone oil from the surface.

Immediately after baking, spray a pretreatment liquid (also called silicone coating, mainly to increase adhesion) onto the silicone surface.

Use the UV flatbed printer to print the graphics.

Bake the silicone again at 200°C for 20-30 minutes to cure the inks.

Following these baking steps, the finished printed product should have no issues and the printed graphics can bend.

In some cases when the silicone oil is difficult to treat, a degreaser may be used to remove oil from the silicone surface.

If you are interested in UV printing solutions for silicone products, please contact us. We are a professional UV printing solution provider with various printer models to choose from, sure to have one suitable for your needs.